Vertical Ramp

Vertical ramps can be controlled electro-hydraulically and brought to a completely vertical position when they are not in use. They save space. It is easy and economical to install because it does not require pits. Standard sizes are 2000x1500 mm. The dynamic load capacity that can pass over it is determined as 6 tons. Please contact with us for special sizes and loading capacities.

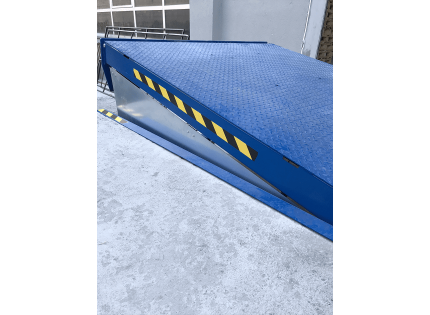

Mini Ramp

Manual loading ramps offer a reliable, economical and ergonomic solutions for fundamental loading operations. Manually operated ramps, which act as a bridge between the truck and the facility floor, are a loading solution that does not require power supply and energy costs. Standard sizes are 1900x650 mm. Please contact with us for special sizes and loading capacities.

TECHNICAL FEATURES OF LOADING RAMP:

Loading ramps provide maximum loading speed and efficiency by establishing a permanent bridge between the loading area and the truck in fields where there are lots of goods’ shipment in and out.

The standard loading ramp has 2 main parts. First one is the platform and the second one is the lip. Main platform standard sizes are 200×250 cm, and can be preferred in different sizes due to highness of warehouse and wideness of the vehicle. Special production ramps should be preferred for unusual truck and warehouse heights. The ramp consists of a hydraulic pump, valves and two pistons, one large and one small, which provides the movement to the platform. The large piston makes the platform moving, and the small piston makes the lips moving. The valves control the movements of these pistons respectively.